KEY FACTS

USES

- Industrial FacilitiesOil & Gas TanksMarine EnvironmentsWater and Waste Water TreatmentCold Storage FacilitiesFood Processing Facilities

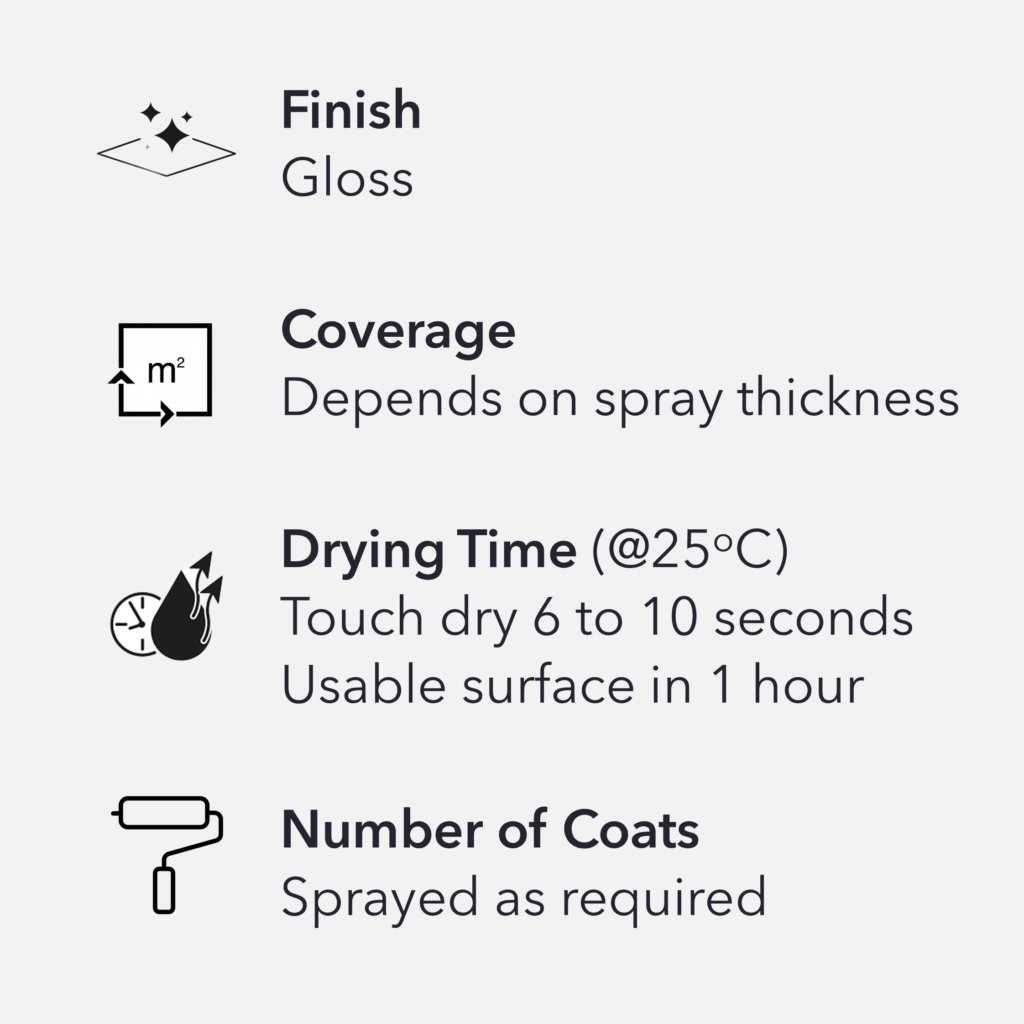

Polycoat 750D is a fast set, rapid curing, 100% polyurea, flexible, two-component spray coating material. 750Dis used by itself or in combination with other materials to produce coatings, liners, wearing courses, and resilient surfaces on metal substrates. Its extremely fast gel time makes it suitable for applications down to -50oC and up to +200 oC without special conditioning of the component resins and isocyanates.

Reviews

There are no reviews yet.