KEY FACTS

USES

A primer and coating for

high temperature applications

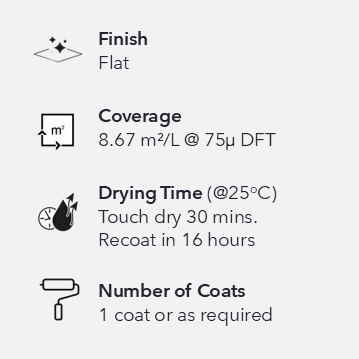

A two-pack moisture curing inorganic ethyl zinc silicate primer and coating. Silprotect is a zinc rich product that cures into an anticorrosive, hard-wearing, high impact protective coat that can withstand temperatures up to 600 oC. Ideal for high temperature industrial applications.

Reviews

There are no reviews yet.