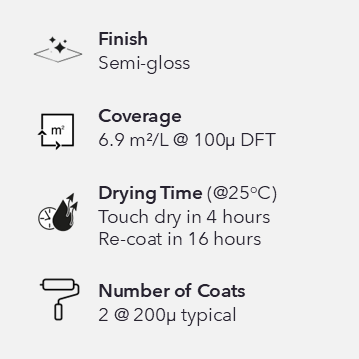

KEY FACTS

USES

- Immersed structures

- Buried structures

- Overground structures

Epoxytar-HQ is a two pack high quality polyamide cured coal tar epoxy coating. A tough and hard wearing coating suitable for marine and industrial atmospheric exposure and immersion in water. Epoxytar-HQ can be used with Cathodic protection and it cures in low temperatures.

Reviews

There are no reviews yet.