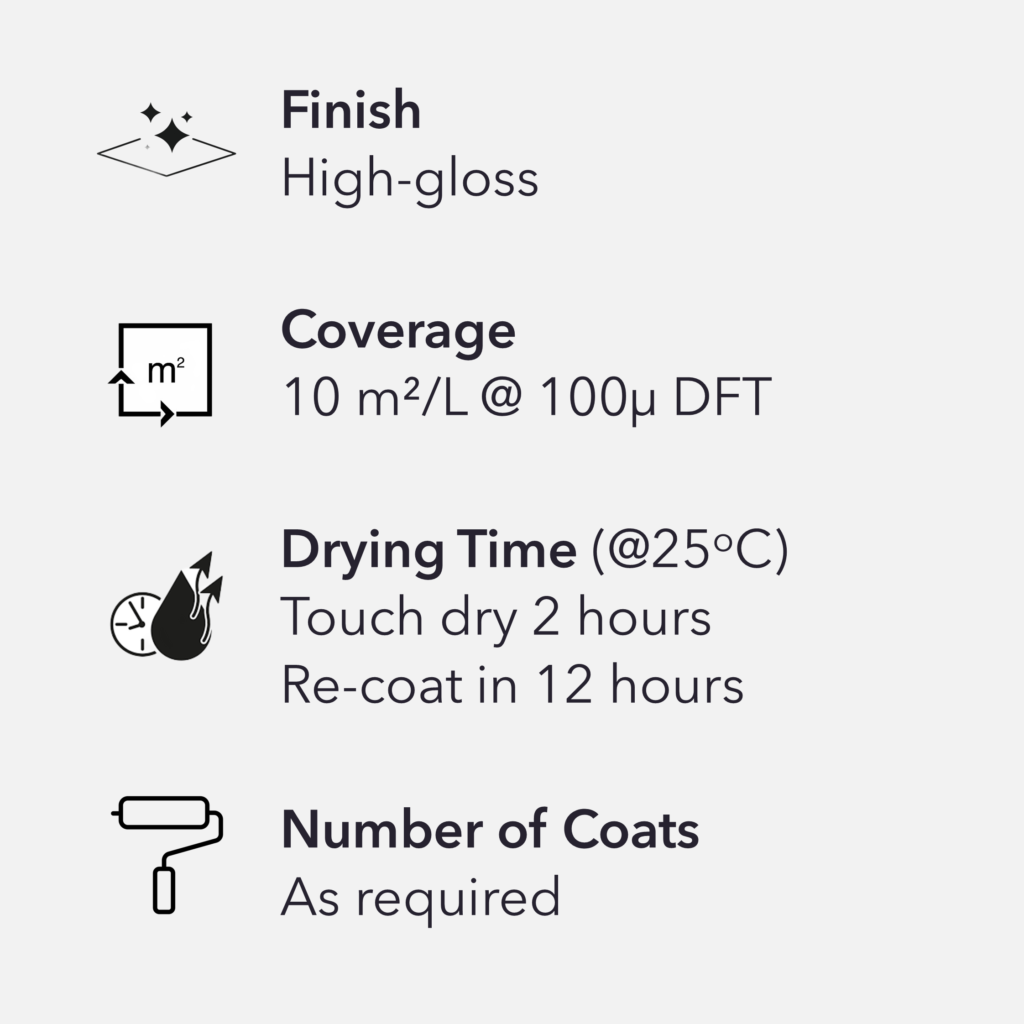

KEY FACTS

USES

- Surgery rooms floorsIntensive care units floorsControl roomsAnti-static tank lining

A solvent free two-pack polyamine cured antistatic/antibacterial epoxy coating designed to be used in areas where an antibacterial or antistatic floor is needed. Ideal for use as a flooring system in surgery rooms, intensive care units, control rooms as well as inside tanks where an antistatic flooring is required.

Reviews

There are no reviews yet.